Chiller (Chilled Fluid) Units

<

►

>

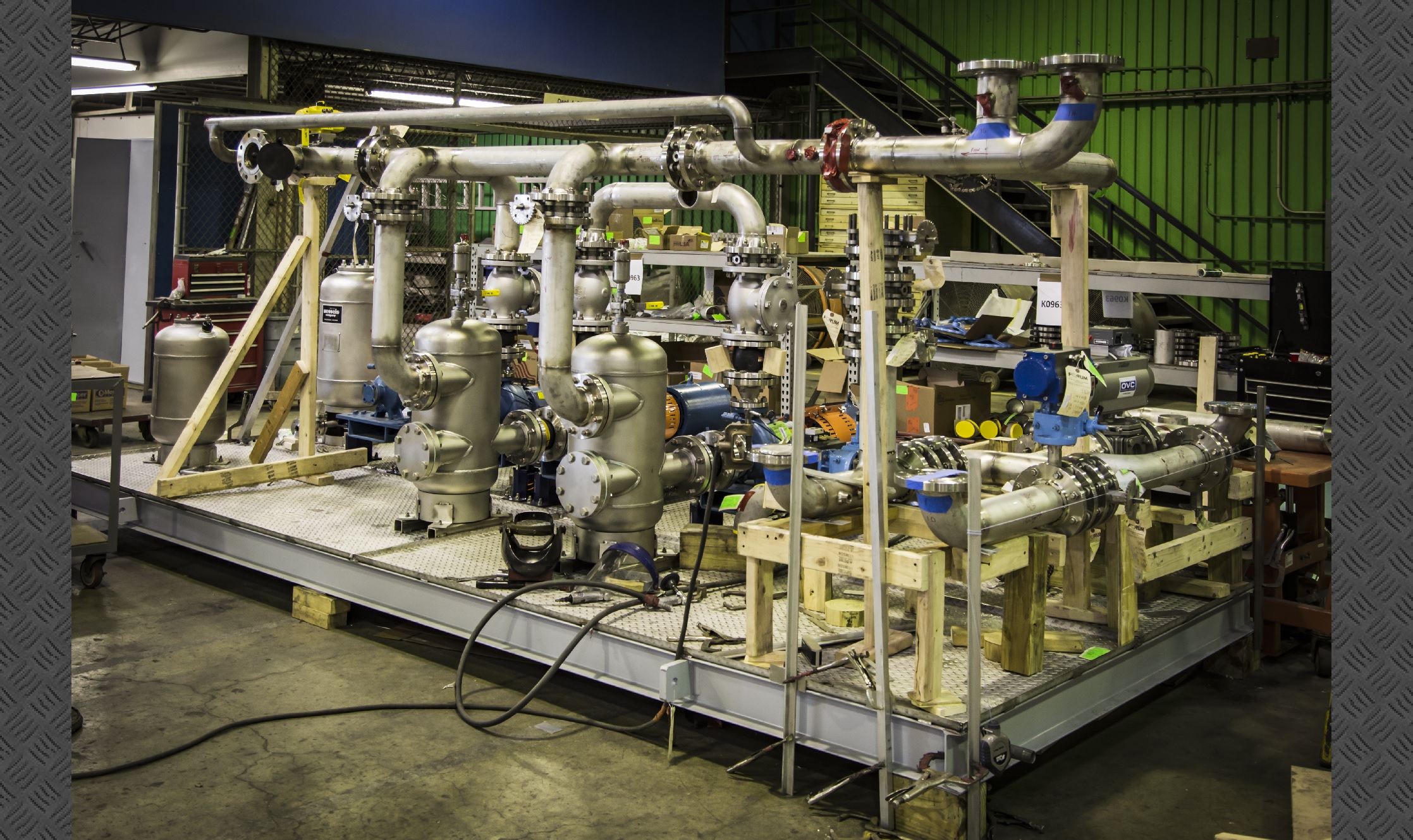

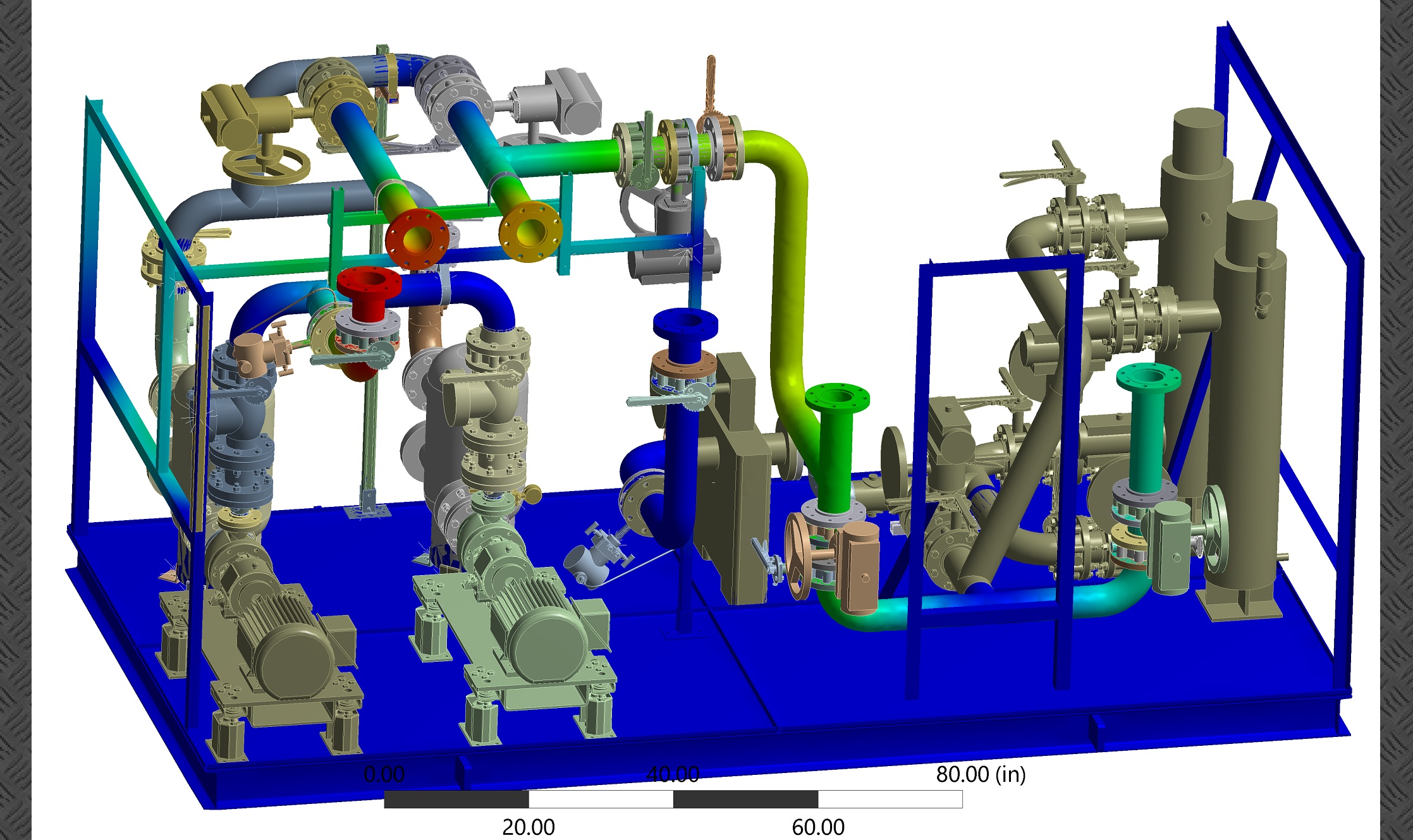

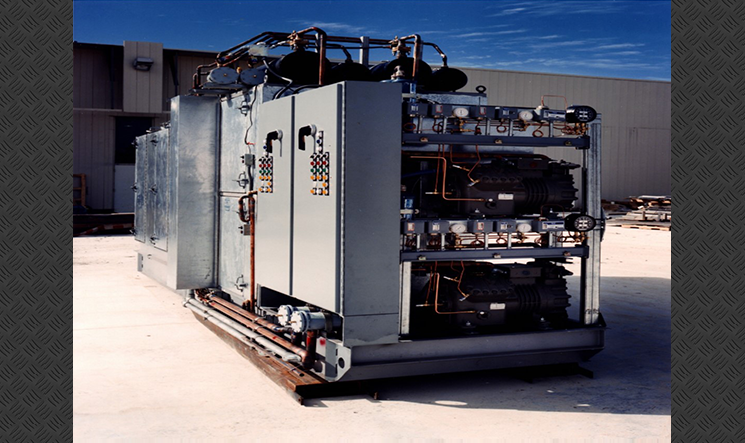

Ellis & Watts designs, qualifies, manufactures, and tests custom chillers to provide temperature controlled fluid for use in comfort and mission-critical environmental and process cooling applications.

Ellis & Watts Liquid Chillers can be designed for - CLICK TO SEE FULL LIST

- air-cooled or water-cooled condensing

- a wide variety of fluids with supply fluid temperatures down to -100F

- analog, relay-based controls to address qualification, cyber security, or EMI/RFI concerns or digital control systems

- a variety of compressor technologies to optimize efficiency, reliability, and life-cycle cost objectives

- operation at ambient temperatures from -40F to +140F

- various materials of construction to meet structural integrity, corrosion resistance, weight, and cost requirements

- seismically qualification per IEEE 344

- environmentally qualification per IEEE 323

- various power supply, controls, and piping options

- hazardous duty applications (explosion proof)

- EMI/RFI suppression with verification testing

- portable or mobile applications, including shock and vibration isolation

- documented performance compliance and proper operation through factory testing at full and part-load conditions

- transportation, rigging and installation constraints with modular construction

Complete units and components can be provided with compliance to - CLICK TO SEE FULL LIST

- ASME AG-1

- ASME NQA-1

- IEEE 323, IEEE 334, and IEEE 344

- 10CFR50 Appendix B

- Heat Exchangers to ASME Section VIII or ASME Section III

- Compressors to ASME AG-1 Section RA

- Motors to ASME AG-1, IEEE 323, IEEE 334, IEEE 344, and NEMA MG-1

- Motor wiring to IEEE 383

- Motor insulation to IEEE 117

- Instruments to ASME AG-1 Section IA

- Compliance to IEEE 7-4.3.2 Standard Criteria for Digital Computers in Safety Systems of Nuclear Power Generating Stations

- Compliance to IEEE 603 Standard Criteria for Safety Systems for Nuclear Power Generating Systems

- Compliance to IEEE 1012 Standard for Software Verification and Validation

Past projects in which Ellis & Watts successfully met stringent liquid chilling compliance requirements include - CLICK TO SEE FULL LIST

- US Navy

- Westinghouse Electric Company AP-1000 System

- Almaraz NPP – Spain

- Lungmen NPP – Taiwan

- MIT Deep Submergence Rescue Vehicle

- NASA Viking Ground Support

- F-14 Control System Electronic Shop

- NASA Laser Cooler